The major concern while determining the type of generator which serves best for your environment must be getting the right electrical configuration. The electrical configuration usually consists of the Phase, Voltage, kW and Hertz that are best suited for the user’s application. To elaborate on how all of it works, the basic understanding of what a generator set includes is really helpful. A generator set or commonly known as a genset, consists of two major components – an industrial engine (typically diesel, natural gas or propane) and a generator end. The engine of the generator produces horsepower and RPM, and the end converts it into electricity.

Explaining Phases

Single-Phase Generators

Single-Phase Generators are used for smaller single phase loads. These gensets typically do not go above 40 kW. They are commonly used in residential environments and have a power factor of 1.0.

3-Phase Generators

3-Phase Generators are used mainly for large scale industrial power generation. These gensets can provide both single and 3-phase power for operating industrial motors with much higher horsepower. They branch power out for separate lines and are generally more flexible. They are typically used in the commercial environments. They have a power factor of 0.8.

Increase Power Output Rating

The consumers can convert single-phase to 3-Phase power and gain approximately 20-30% kW output power rating. But for doing so, the end needs to be re-connectable and you also need to account for load balances and a few other variables.

De-Rating (converting from 3-phase to single-phase)

De-Rating or the process of converting from 3-Phase to Single-Phase typically reduces your kW output rating round about 30%. For an instance, a 100kW 3-phase generator would drop up to 70 kW when converted to Single-Phase from 3-Phase.

- To calculate the Adjusted Power produced after de-rating accurately, always try and de-rate from the kVA rating instead of the kW rating. The formula for de-rating is 2/3 kVA. You can then convert it to kilowatts from there if required.

- To de-rate the genset, the generator end of that genset must have 12 or 10 leads that can be reconnected. The single-phase loads do not affect the load on the engine itself as long as the user does not go over the rated amperes or amps on an individual line.

- The genset is rated and limited by its electrical capacity based on the generator end and really does not have much to do with the engine of the generator.

Common Voltages on Commercial Generator Sets

Single-Phase

- 120 Volt

- 240 Volt

- 120/240 Volt

3-Phase Generator:

- 208 Volt

- 120/208 Volt

- 240 Volt

- 480 Volt (standard for industrial genset)

- 277/480 Volt

- 600 Volt (mainly for areas in Canada)

- 4160 Volt

The voltage requirements vary greatly based on the location of the consumer and the type of equipment. The other voltage options include; 220, 440, 2,400, 3,300, 6,900, 11,500 and 13,500.

How to Calculate Your Required Voltage

To configure the voltage according to your needs, it is advised to always consult with an electrician or electrical contractor to evaluate your environment and determine the various work-loads specific to your facility. A professional will also take other variables into account such as total voltage supplied to the building, maximum current or amperes, the horsepower output of the electric motor and several other factors. Calculate the estimated power required and use the amperage charts available at the manufacturers’ website. To help our customers calculate the right voltage for their generator setup, here are the key factors that must be taken into consideration:

- Determine the required voltage and power that needs to be supplied to your facility.

- Calculate the maximum amperage required for your specific equipment to perform optimally. If the amperage is unknown, the alternator amperes for 3-Phase alternators can be typically found on the reference charts to determine the size of circuit breaker needed for your generator.

- In case of industrial motors, the required startup amperage must be taken into account. Several motors run on less kW but require much higher starting kW. For an instance, if the average running load is 90kW, the motor may require 200kW or even higher at startup. The Electric Motor Horsepower should also be evaluated. Some Electric Motors come with the “Soft Starter” technology so they control the acceleration by applying voltage. All this information is provided on the data tag for some industrial motors.

- Utility Frequency is another key factor in determining the right voltage configuration. The majority in U.S and many parts of Asia, operate at 60 Hz where as the rest of the world operates at 50 Hz. Many airplanes and huge ships utilize a specialized 400 Hz frequency. To configure the utility line power at a different frequency, a frequency converter can be used but there are some additional factors to take into consideration. Most gensets can convert the frequency but some generators may not function properly or require additional parts and customization. It is advised to consult your generator manufacturer for additional details regarding these situations.

Configuring the Voltage of a Generator:

Something that our expert technicians have to do every few days is to adjust the voltage of a generator to meet all the various combinations and specific electrical requirements of our customers. Unlike voltage adjustment, which can be done on most generators, your specific options are always limited on the basis of generator end you are using.

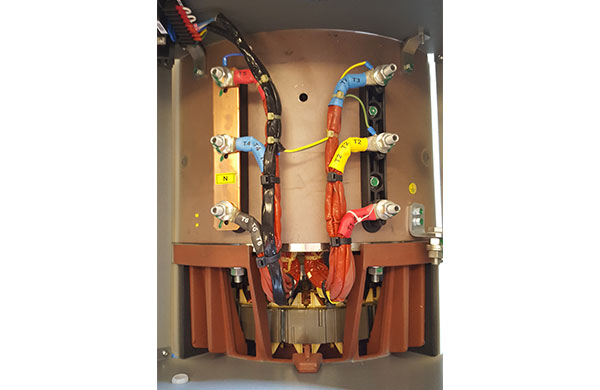

The adjustment of voltage is a comparatively technical electrical procedure which involves the adjustment of the leads on the generator end. Typically 10 or 12 leads are reconfigured in most 3-Phase Gensets. These 10 or 12 leads are rearranged and reconnected so to adjust their route to control panel and some other places according to our requirements. The wires are well insulated, sensing wires are configured if required and then additional changes are made according to our needs. This is the point where the dogleg and double delta (also known as Zig-Zag), Y-Configuration and other various wiring schemes are often referenced. To learn more about these terms, see the articles on Phase Conversions. The range of adjustable voltage on a 3-Phase Genset is from 208V to 480V, from 480V to 240V or a number of other combinations and phases using all the available voltage as long as the generator end is re-connectable.

The primary component that determines the reaction of generator while altering the phase and/or voltage is the generator end. Altering voltage should not harm or strain the unit in any capacity if done properly. The availability of two or more system voltages from the standby Genset is crucial for many customers. It includes electric motors operating at 480 Volt, appliances and production equipment utilizing 208 Volts, and a few smaller work-loads and power tools running at 240 Volt. This can be achieved with a 3-Phase generator either by using a changeover switch or getting a dual voltage generator that is specifically made for that purpose. It is to be kept in mind however, that the user is not able to output multiple voltages from a single generator simultaneously. The output needs to be switched manually to each different voltage or a transformer can also be utilized to perform the same task.

While considering the voltage adjustment, there are a few limitations to be kept in mind. The high voltage generator sets or specialized gensets are not feasible for altering the voltage. The voltage can be changed from 600V to 480V but the other way around. Sometimes on 3-Phase Gensets, certain elements can be tough to access and very hard to work around. For an instance, these gensets might have flexible conduit that wraps, panel doors fixed in odd places, or tight enclosures which don’t allow our technicians to access easily. The barrel and wiring on 3-phase generator ends can also be tough sometimes even if there’s always a way to access them. Another important thing to be considered is that some generator ends are not re-connectable. Hence, the wiring options and schemes available are very limited for these types of generators.

One other common practice while altering voltage of generator is that we update the components and review several other potential equipment considerations in our customers’ systems which involve the following:

Gauge Replacements:

At Rich Motor, we usually have to replace a number of gauges whenever we alter the voltage on an old generator in order to read the new output levels. The newer digital control panels can usually be reprogrammed, which is a big advantage of these control panels.

Circuit Breakers:

The circuit breaker(s) on the units are regularly changed out to accommodate the amperage requirements of our customers. Typically, the circuit breaker is attached to the generator end. Breaker is a critical component that protects the generator by ensuring that the users do not exceed the rated amperage for that unit. Either everything is dependent on one breaker or split out for some specific reasons according to the customers’ needs. In order to do so, we may change the configuration to some components like utilizing one 1200 Amp breaker or two 600 Amp ones.

Voltage Regulator:

On many generators, the sensing wires that run to the regulator and/or control panel need to be adjusted carefully while reconnecting the leads to a different voltage. You can burn out the board or cause some other damage if sensing wires are not adjusted properly. You can adjust voltage and do all the regulating quite easily from the voltage regulator integrated into the control panel for most modern generators. This is a major advancement but this feature also makes the board replacement quite expensive because of added functionality. For the same operations, the older gensets usually have a separate piece of equipment. A consistent voltage is automatically maintained by these voltage regulators to assure a consistent output by your equipment.

Transformer:

Some of the wiring may also be re-configured as well to accommodate the new voltage, if your system utilizes a transformer.

Automatic Transfer Switch (ATS):

For this kind of adjustment, the required amperage must also be determined because an ATS is a key component that fortifies your genset to take over automatically during a utility outage. When the power comes back on, it shuts down automatically.

Conclusion:

There are a number of ways to go when it comes to phase and voltage combinations, configurations, and conversions. It is advised to ask for professional help from a commercial electrician or experienced generator technician as it can be an involved process. If you have any queries regarding any issues covered in this article, would need some help in sizing a genset, or if you would like our assistance for determining the best options for your specific environment, just call us at 855-657-7600 or you can Contact Us online.

About Us

Rich Motor Company (RMC) is the most trusted supplier and Quality manufacturing of generators powered by Kubota, john deer, and RMC G-drive engines powered by Cummins offering power and O&M services in the UAE and The Middle East.

Contact Us

Follow Us On Social Sites